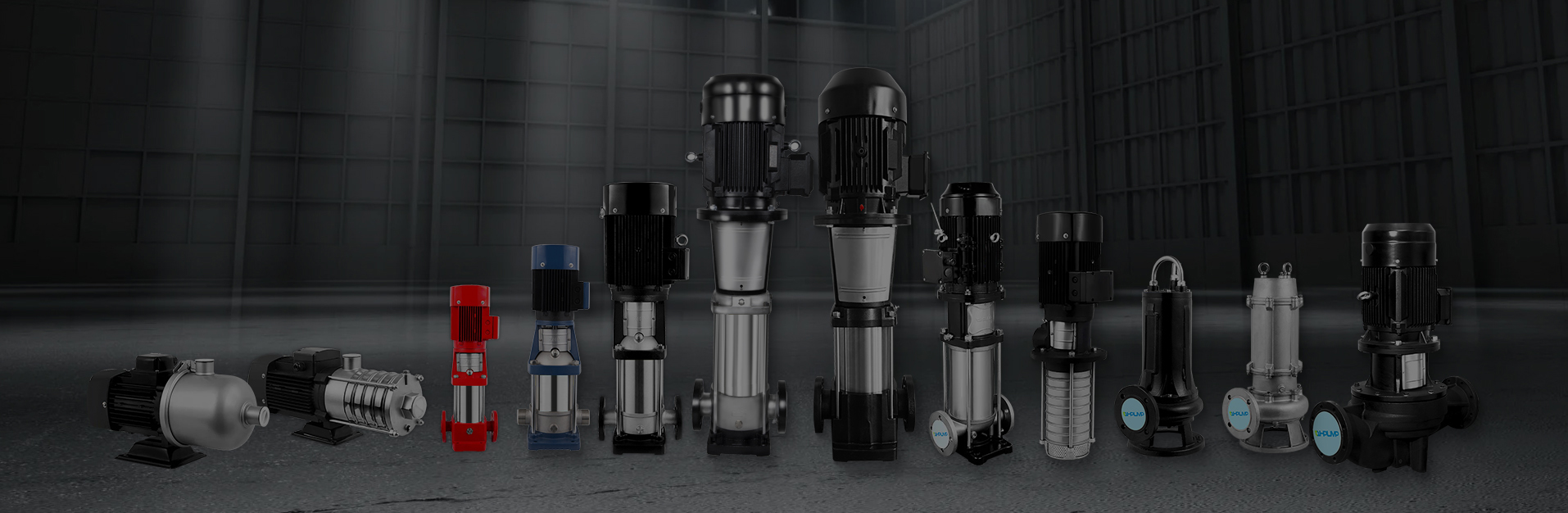

Zhejiang Zehao Pump Industry Co., Ltd. 는 과학연구, 제조, 판매를 일체화한 스테인레스 스틸제 다단 원심 펌프의 전문 메이커입니다. 설립 이래 '성실과 혁신'을 발전 목표로 삼아 전문적이고 신속한 서비스를 고객에게 제공하는 것을 사명으로 삼고 있습니다. 주요 제품은 ZHLF/ZHL 시리즈 입형 다단 원심 펌프, TD 파이프라인 순환 펌프, 수평 다단 원심 펌프, 침지 다단 원심 펌프, 오수 펌프 등 다양합니다. 성능 지표와 기술 파라미터는 국내 최첨단 수준에 이르고 있으며, 공업용·가정용 급수, 난방, 여과·수송 시스템, 소방 시스템, 각종 관개 시스템, 공작 기계 냉각 시스템, 오수·폐수 처리 등, 폭넓은 분야에서 사용되고 있습니다. 당사는 선진적인 생산·시험 설비와 강력한 기술력을 갖추고, 원재료의 선별, 공정 관리, 제품 판매에 이르기까지 모든 면에서 엄격한 관리 시스템을 구축하고, 고품질의 제품과 충실한 서비스로 고객의 요구에 부응하고 있습니다.

회사 소개

8+년

경험

私たちについて

Zhejiang Zehao Pump Industry Co., Ltd.

뉴스 센터

뉴스 업데이트

-

관리자 2025-08-29

침수 다단계 원심 펌프를 표준 수직 또는 수평 원심 분리 펌프와 구별하는 설계 특성은 무엇입니까?

침지 다단계 원심 펌프 공정 액체에 직접 잠긴 유압 섹션으로 작동하도록 설계된 특수 카테고리의 펌프입니다. 이 구조적 차이는 표준 수직 및 수평 원심 펌프와 차별화되며 특정 응용 분야에 대한 성능, 신뢰성 및 적합성에 영향을 미치는 몇 가지 고유 한 설계 특성을 제공합니다. 이러한 차이를 이해하는 것은 연... 계속 읽기

계속 읽기

-

관리자 2025-08-22

어느 산업에서 가장 일반적으로 적용되는 수직 멀티 스티지 펌프는?

수직 다단계 펌프 비교적 소형 발자국 내에서 고압, 일관된 흐름 및 효율적인 성능을 제공하는 능력 때문에 많은 산업에서 널리 사용됩니다. 수직 설계는 바닥 공간이 제한되어 있지만 안정적인 펌핑이 필수적 인 응용 분야에서 특히 가치가 있습니다. 이러한 펌프가 가장 일반적으로 적용되는 산업을 이해하면 현대 시... 계속 읽기

계속 읽기

-

관리자 2025-08-15

수평 펌프와 수직 멀티 스티지 펌프를 구별하는 것은 무엇입니까?

에이 수직 다단계 펌프 주로 여러 가지 주요 측면에서 수평 펌프와 다릅니다. 설계, 공간 요구 사항, 성능 및 응용 프로그램 적합성 . 자세한 비교는 다음과 같습니다. 1. 방향과 디자인 수직 다단계 펌프 : 이름에서 ... 계속 읽기

계속 읽기

-

관리자 2025-08-09

수평 다단계 펌프 : 고압 응용을위한 엔지니어링 우수성

수평 다단계 펌프는 신뢰할 수있는 고압 액체 전달이 필요한 산업 및 상업 환경에서 중요한 솔루션을 나타냅니다. 이 강력한 기계는 단일 케이싱 내의 여러 임펠러 단계를 결합하여 에너지 효율을 유지하면서 우수한 압력 기능을 달성합니다. 급수 시스템에서 산업 공정에 이르기까지 수평 다단계 펌프는 단일 단계 펌프가 부족한 ... 계속 읽기

계속 읽기

Horizontal End-Suction Pumps for Industrial and Civil Use: A Complete Guide

Horizontal end-suction centrifugal pumps are widely recognized for their reliable performance, simple structure, and broad range of applications across industrial and civil sectors. These pumps are characterized by having both the suction and discharge ports positioned on the same side of the pump casing. The pump body is installed horizontally, and the rotating impeller generates centrifugal force to draw in fluid through the suction port and discharge it through the outlet. With stable pressure, corrosion resistance, and ease of operation, horizontal end-suction pumps have become essential equipment in many fluid transportation systems.

One of the primary advantages of horizontal end suction centrifugal pumps lies in their versatility. They are capable of handling a wide variety of media, including clean water, sewage, light oils, and various chemical solutions. This adaptability makes them suitable for a diverse range of working conditions, including environments that require the handling of corrosive or abrasive fluids. Their straightforward design not only facilitates easier maintenance but also reduces the likelihood of mechanical failure, contributing to long-term operational efficiency and cost-effectiveness.

In industrial applications, horizontal end-suction pumps play a critical role in numerous sectors. For example, in the petrochemical industry, they are used to transport chemical fluids within process systems. In power plants, they help circulate cooling water and other necessary fluids throughout the system. Papermaking facilities rely on these pumps for process water circulation, while wastewater treatment plants use them for sludge handling and effluent management. The robust construction and dependable performance of horizontal end suction centrifugal pumps make them indispensable in these high-demand environments.

Zhejiang Zehao Pump Industry Co., Ltd., a professional manufacturer specializing in stainless steel multistage centrifugal pumps, also produces a variety of other pumping equipment designed to meet the needs of modern industry. With a commitment to “integrity and innovation,” the company integrates scientific research, manufacturing, and sales to offer high-performance pumping solutions. The company’s range includes not only vertical multistage centrifugal pumps such as the ZHLF/ZHL series, but also TD pipeline circulation pumps, immersed multistage centrifugal pumps, sewage pumps, and of course, horizontal multistage and horizontal end-suction centrifugal pumps. These products have achieved advanced performance standards within the domestic market.

In civil engineering and municipal systems, horizontal end-suction pumps are frequently applied in water supply and drainage systems, agricultural irrigation, and urban wastewater management. Their ability to handle large flow volumes with consistent pressure makes them well-suited for these uses. In rural areas, they assist in the distribution of irrigation water to agricultural fields, while in urban infrastructure, they support the delivery of potable water and the removal of sewage and stormwater. The ease of installation and reliability of these pumps ensure their continued use in essential public services.

Zhejiang Zehao Pump Industry Co., Ltd. has positioned itself as a reliable partner for both industrial and civil clients by maintaining high manufacturing standards and strict quality control. The company employs advanced production and testing equipment and has established rigorous management systems that cover everything from raw material selection to final product delivery. This ensures that every horizontal end suction centrifugal pump and other pump type meets the specific needs of its users, providing both performance and durability. Zehao’s technical expertise and customer-focused approach enable them to offer tailored solutions that improve system efficiency and reduce operational downtime.

Beyond their technical benefits, horizontal end-suction pumps also offer cost advantages. Their relatively simple mechanical structure leads to lower production and maintenance costs compared to more complex pump types. Additionally, their compact design requires less space for installation, making them an ideal choice in settings where space is limited. The low energy consumption and high hydraulic efficiency of these pumps further contribute to reduced operating costs over time, supporting long-term sustainability for both industrial enterprises and public facilities.

As a key player in the pump manufacturing industry, Zhejiang Zehao Pump Industry Co., Ltd. continues to expand its product offerings and improve its technologies to meet evolving market demands. Its horizontal end suction centrifugal pumps are widely used not only in China but also in international markets, where their reliability, efficiency, and cost performance are highly valued. With a strong emphasis on quality, technical innovation, and customer satisfaction, Zehao is well-equipped to support the pumping needs of industries and municipalities worldwide.

In conclusion, horizontal end-suction pumps provide an optimal solution for fluid transportation across a variety of sectors. Their robust design, operational reliability, and adaptability to different media make them indispensable in both industrial and civil engineering applications. Manufacturers like Zhejiang Zehao Pump Industry Co., Ltd. play a critical role in advancing pump technology and delivering high-quality products that meet the demands of modern infrastructure and industry. Whether for chemical processing, wastewater treatment, or municipal water distribution, horizontal end suction centrifugal pumps remain a dependable choice for efficient and cost-effective liquid handling.

영어

영어